Richiamami

-

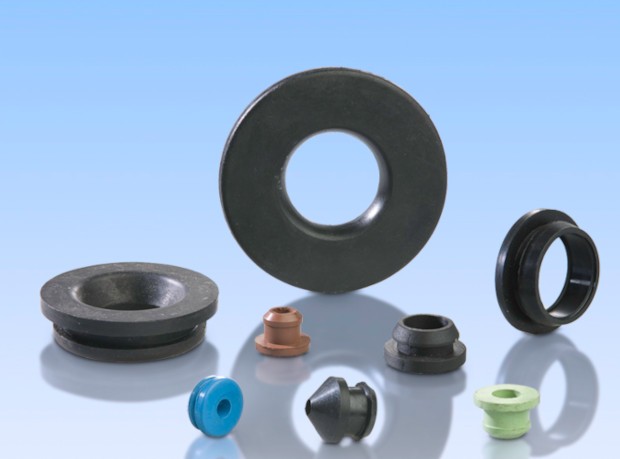

Area espositiva

Vieni a trovarci e

scopri tutti i nostri prodotti -

Forniture industriali

Richiedi un preventivo per la fornitura

di grandi quantitativi -

ISO 9001

Prodotti di qualità

e certificazione ISO 9001:2015 -

SUPPORTO MULTILINGUA

Rispondiamo in Italiano,

Inglese e Tedesco